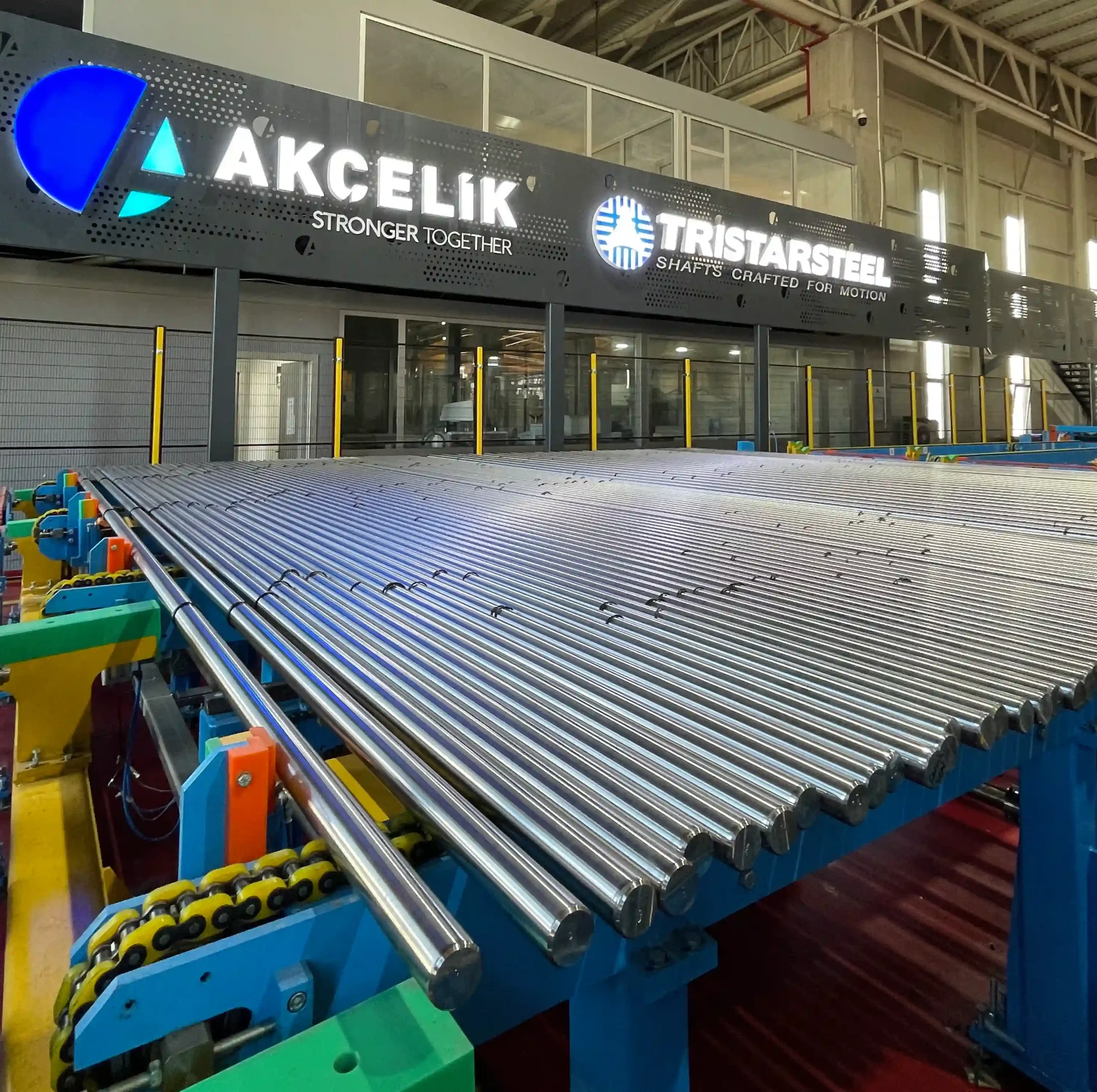

Chrome Plated

Bars

Akçelik Demir Çelik, with the partnership signed with Tristar Steel Srl located in Targoviste/Romania in July 2021 and the new facility opened in Çayırova/Kocaeli Turkey, produces hard chrome plating between 5 mm and 130 mm in steel standards E355+SR, C35E, C45E, Cf53, C60E, 20MnV6, 38MnVS6, 42CrMo4+QT, E355+SR, X46Cr13, X90CrMoV18 - optionally with induction hardening.

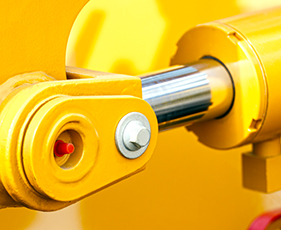

With a total annual production capacity of 40,000 tons, it supplies products to global industry-leading customers by producing hydraulic cylinders and pneumatic/gas cylinders, as well as shafts for linear motion systems.

You can examine Akçelik products, which have superior corrosion resistance, maximum automation capability in the production phase, minimum error and unique quality, on this page.

Quality Control During Production

Ground Rods Before Chrome Plating

100% each single bar

- Visual inspection

- Dimension

- Roughness

- Roundness

- Surface Hardness SHD (optional)

Final Grinding After Chrome Plating

100% each single bar

- Visual inspection

- Dimension (3-point analysis)

- Roughness (3-point analysis)

- Roundness (3 points)

- Chrome Thickness (3-point analysis)

- Corrosion resistance in each production batch

Chrome Plating Process

Daily Control

- Bath temperature

- Chrome concentration

- Amperage and voltage

- Chrome bath chemistry

Additional Laboratory Control

For each production batch

- Micro hardness of the chrome layer

- Micro and macro structure

- Micro cracking

- Verification of chrome adhesion

- Corrosion resistance

Application Areas

Lifting and Handling Equipment

Tree Cutting and Forestry Control Machines

Wind Turbines and Renewable Energy Systems

Pneumatic Cylinders for Medical Equipment

Construction Machinery

Maritime and Offshore Industry

Steel Production Industry Equipment

Mining Equipment

Bodybuilding and Fitness Equipment

Automotive Manufacturing Industry

Agricultural Machinery

Printing and Separation Machines

Shock Absorbers and Gas Springs